Forging txheej txheem ntawm thoob hniav & Adapter

Peb txhua tus paub tias tag nrho cov peev txheej castings muaj ntau ntawm cov txheej txheem tsim khoom.CFS thoob cov hniav txais kev nqis peev casting txheej txheem, tseem hu ua poob ciab casting, nrog rau cov qauv siv quav ciab, kev sib dhos ntoo, lub plhaub tsev, dewax, hlau casting thiab lwm yam kev kho mob tom qab.Qhov loj tshajkom zoo dua ntawm peev castingyog tias nws tuaj yeem tau txais qhov raug qhov loj me, qhov zoo ntawm qhov tiav, thiab nrum tag nrho cov alloy complex duab.

Hauv qab no yog cov txheej txheem casting ntawm thoob cov hniav hauv peb qhov chaw tsim khoom hauv txhua kauj ruam:

Kauj Ruam 1. Tsim cov thoob cov hniav hauv qhov sib txawv thiab qhov ntev raws li kev xav tau ntawm kev lag luam.

Kauj Ruam 2. Nruab nrog tag nrho cov txheej txheem pwm ua cov cuab yeej thiab pab pawg kws tshaj lij, peb tuaj yeem siv tshuabcuab yeejrau txhua yam kev nqis peev casting, suav nrog thoob cov hniav.

Kauj Ruam 3. Ciab qauv ua yog thawj kauj ruam rau castingthoob hniav.Cov qauv siv quav ciab yog siv los ua cov kab noj hniav ntawm lub plhaub refractory.Yog li kom ua tau zoo thoob cov hniav nrog qhov loj qhov tseeb thiab qhov chaw tiav, cov qauv siv quav ciab nws tus kheej yuav tsum muaj qhov raug siab thiab nto tiav.Tab sis yuav ua li cas thiaj li tau txais kev tsim nyog siv quav ciab qauv?Dhau li tsim pwm zoo, peb tseem yuav tsum xaiv cov khoom siv zoo nkauj thiab cov txheej txheem wax zoo.Qhov zoo ntawm cov qauv siv quav ciab los ntawm CFS yog qhov qis melting point, zoo nto tiav & qhov ntev, siab zog thiab lub teeb yuag.

Kauj ruam 4. Tsob ntoo los ua ke yog cov txheej txheem uas sticking wax qauv ntawm thoob cov hniav rau sprue gating system.

Kauj Ruam 5. Cov txheej txheem tseem ceeb ntawm lub tsev plhaub muaj xws li:

a.Unoil ntawm tsob ntoo sib dhos - Txhawm rau txhim kho lub peev xwm ntawm txheej txheej wetting, peb yuav tsum tshem tawm cov roj saum npoo ntawm cov qauv siv quav ciab.

b.Dipping ntoo los ua ke rau hauv ceramic txheej thiab txau xuab zeb rau saum npoo.

c.Qhuav thiab harden ceramic sheel.Txhua lub sij hawm txheej txheej ntawm ceramic sheel txheej yuav tsum tau qhuav thiab hardened.

d.Tom qab ua tiav ntawm lub plhaub ceramic, peb yuav tsum tshem tawm cov pwm pwm los ntawm lub plhaub, cov txheej txheem no hu ua dewax.Raws li cov txheej txheem cua sov sib txawv, muaj ntau ntau txoj kev dewax, feem ntau siv yog tib txoj kev ua haujlwm siab.

e.roasting ceramic plhaub

Kauj Ruam 6. Pouring hlau ua kua alloy los sau cov kab noj hniav ntawm lub plhaub.

Kauj Ruam 7. Kev ntxuav cov thoob cov hniav, suav nrog tshem tawm lub plhaub, ntu sprue, txuas cov khoom siv refractory thiab ntxuav tom qab kev kho cua sov zoo li nplai.

Kauj ruam 8. Tom qabKev kho cua sov, lub koom haum qauv ntawm thoob cov hniav yuav zoo ib yam, thiab hnav tsis kam yuav zoo heev, yog li ntawd lub neej kev pab yuav zoo dua ob zaug dua ua ntej.

Kauj Ruam 9. Los ntawm kev tshuaj xyuas tag nrho cov khoom siv thiab cov khoom siv kho tshuab rau thoob cov hniav, peb tuaj yeem tiv thaiv cov khoom tsis tsim nyog rau kev ua lag luam.

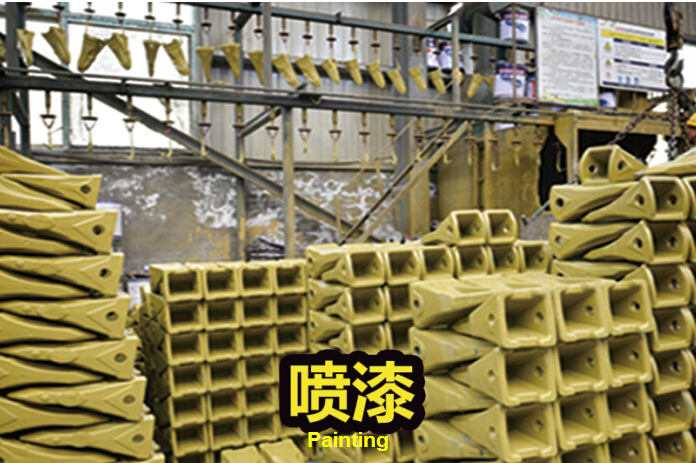

Kauj Ruam 10. Kev pleev xim rau hauv cov xim xws li daj, dub, ntsuab, ect kom haum rau ntau hom thiab tshuab.

Kauj Ruam 11. Ntim thoob cov hniav hauv cov ntaub ntawv ntoo los ntawm kev puas tsuaj thiab xa mus rau peb cov neeg siv khoom.