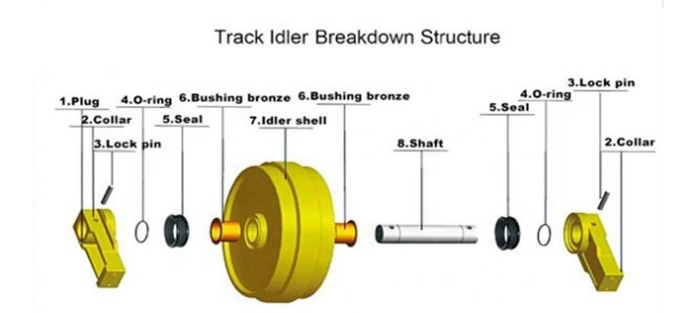

Pem hauv ntej idler yog ib qho tseem ceeb nyob rau hauv lub undercarriage system ntawm taug qab cov khoom hnyav xws li excavators, bulldozers, thiab crawler loaders. Nyob rau hauv pem hauv ntej kawg ntawm txoj kev sib dhos, tus idler coj txoj kev khiav thiab tswj qhov nruj nro, ua lub luag haujlwm tseem ceeb hauv kev ua haujlwm thiab kev ua haujlwm ntev ntawm tag nrho cov kab hauv qab.

Lub luag haujlwm tseem ceeb ntawm Pem Hauv Ntej Idlers

1.Track Tensioning:

Pem hauv ntej idler ua hauj lwm nrog rau lub recoil caij nplooj ntoos hlav thiab tensioning mechanism siv zoo ib yam nro rau txoj kab khiav. Qhov no tiv thaiv sagging ntau dhau los yog overtightening, uas tuaj yeem ua rau ua rau ntxov ntxov ntawm kev sib txuas thiab cov menyuam.

2.Track Alignment:

Nws ua haujlwm raws li cov lus qhia kom taug qab hauv kev sib raug zoo thaum ua haujlwm. Ib tug idler ua tau zoo txo qhov kev pheej hmoo ntawm de-tracking, tshwj xeeb tshaj yog nyob rau hauv hnyav sab loads los yog nyob rau hauv uneven terrain.

3.Load Distribution:

Txawm hais tias nws tsis nqa ntau li ntsug loads li cov menyuam, lub hauv ntej idler pab faib cov dynamic rog nyob rau hauv lub undercarriage. Qhov no minimizes localized hnav thiab pab kom smoother tshuab ua hauj lwm.

4.Kev vibration Damping:

Los ntawm nws txoj kev txav mus los thiab rov ua haujlwm, tus idler pab nqus cov kev poob siab thiab kev vibrations los ntawm kev sib cuag hauv av, tiv thaiv ob qho tib si khiav thiab chassis Cheebtsam.

Cov teeb meem kev hnav khaub ncaws

1.Flange Hnav:Kev sib txhuam tsis tu ncua los ntawm sab kev mus los lossis kev tsis sib haum tuaj yeem ua rau lub idler flanges hnav, ua rau cov kev taw qhia tsis zoo.

2.Nto Pitting lossis Spalling:Kev cuam tshuam loj los yog lubrication tsis zoo tuaj yeem ua rau qaug zog saum npoo.

3.Failure foob:Seal degradation tuaj yeem ua rau lubricant to, nthuav tawm cov kabmob rau cov kabmob thiab ua kom nrawm nrawm.

Txhim kho cov kev coj ua zoo tshaj plaws

1.Kev tshuaj xyuas tsis tu ncua:

Kev kuaj pom pom kev tawg, flange hnav, thiab cov roj xau yuav tsum yog ib feem ntawm kev saib xyuas niaj hnub. Tshawb xyuas qhov txawv txav tsis zoo, vim nws yuav qhia tau tias lub caij nplooj ntoos hlav rov qab tsis ua haujlwm lossis idler misalignment.

2.Taug qab Tension Kho:

Xyuas kom cov khiav nro poob nyob rau hauv lub chaw tsim tshuaj paus specification. Ob qho tib si nyob rau hauv-nruj thiab dhau-nrawm tuaj yeem ua rau idler misalignment thiab puas lub recoil mechanism.

3.Roj thiab lubrication:

Ntau cov idlers raug kaw-rau-lub neej, tab sis yog tias tsim nyog, tswj cov qib lubrication kom zoo los tiv thaiv cov kabmob sab hauv.

4.Undercarriage Cleaning:

Tshem tawm cov av nkos, cov khib nyiab, lossis cov khoom khov nyob ib puag ncig ntawm lub idler kom tsis txhob muaj kev sib txhuam thiab hnav tsis sib xws.

5.Hloov Sijhawm:

Saib xyuas cov qauv hnav thiab hloov cov idlers thaum hnav txwv tau mus txog, feem ntau ntsuas tawm tsam OEM specs. Tsis quav ntsej hnav idlers tuaj yeem ua rau muaj kev puas tsuaj sai rau kev sib txuas, chais, thiab lub caij nplooj ntoos hlav rov qab.

Xaus

Pem hauv ntej idler, txawm tias feem ntau tsis saib xyuas, yog qhov tseem ceeb rau kev taug qab kev ruaj ntseg, nruj, thiab kev ua haujlwm hauv qab. Kev saib xyuas raws sijhawm thiab kev tshuaj xyuas tuaj yeem txo qis lub sijhawm poob qis, txuas ntxiv kev pabcuam lub neej hauv qab, thiab txhim kho lub tshuab tsim khoom.

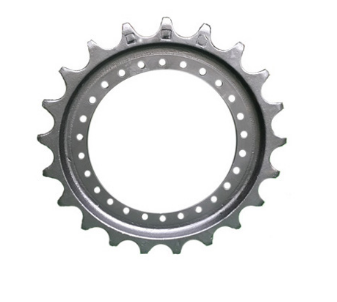

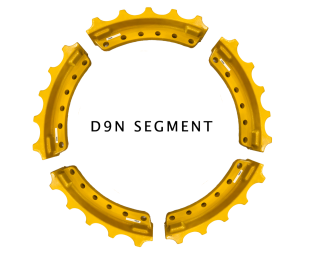

Sprockets thiab Segments: Cov qauv, xaiv, thiab siv phau ntawv qhia.

Sprockets thiab ntu yog qhov tseem ceeb ntawm kev tsav tsheb hauv cov kab hauv qab ntawm cov cuab yeej siv hnyav, suav nrog excavators, bulldozers, thiab mining machinery. Lawv koom nrog cov saw saw bushings kom hloov torque los ntawm qhov kawg tsav mus rau txoj kev khiav, ua rau pem hauv ntej lossis rov qab txav mus.

Sprocket

Ntu

Cov qauv thiab cov khoom siv

Sprockets feem ntau yog ib qho kev sib tsoo los yog forging nrog ntau cov hniav, thaum segmented sprockets (segment) yog modular, bolted ncaj qha mus rau lub hub tsav. Qhov kev tsim segmented no tso cai rau kev hloov pauv yooj yim dua yam tsis muaj disassembling qhov kawg tsav.

High-wear resistance yog qhov tseem ceeb. Feem ntau cov sprockets yog ua los ntawm high-strength alloy steel thiab undergo sib sib zog nqus induction hardening kom tiav hardness ntawm HRC 50-58, kom ntseeg tau ntev hnav lub neej nyob rau hauv ib puag ncig abrasive.

Cov txheej txheem xaiv

Match Pitch thiab Profile:Lub sprocket yuav tsum phim lub suab thiab bushing profile ntawm cov kab khiav (piv txwv li, 171mm, 190mm). Kev sib koom ua ke tsis raug yuav ua rau nrawm nrawm los yog de-mus txog.

Tshuab Compatibility:Nco ntsoov xa mus rau OEM specs lossis cov lej kom paub tseeb tias haum nrog koj cov qauv khoom tshwj xeeb (xws li, CAT D6, Komatsu PC300).

Hniav suav thiab Bolt Qauv:Cov hniav suav thiab mounting qhov qauv yuav tsum ua raws nraim nrog qhov kawg tsav hub kom tsis txhob muaj teeb meem kev teeb tsa lossis iav misalignment.

Cov lus qhia siv

Saib xyuas Bushing kev koom tes:Kev coj khaub ncaws ntau dhau los yog elongation tuaj yeem ua rau cov pob txha hla, ua rau cov hniav puas.

Hloov raws li ib txheej:Nws raug nquahu kom hloov cov sprockets nrog rau cov saw hlau kom tswj tau synchronized hnav.

Tshawb xyuas tsis tu ncua:Cov kab nrib pleb, cov hniav tawg, lossis cov qauv hnav tsis sib xws qhia tau tias nws yog lub sijhawm rau kev hloov.

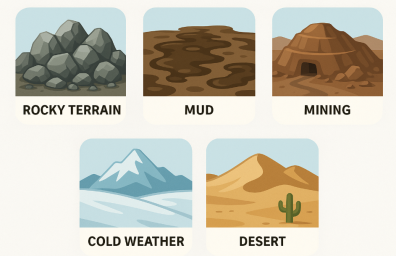

Yuav ua li cas xaiv qhov zoo undercarriage Parts rau txawv chaw ua hauj lwm?

Xaiv cov khoom hauv qab kom raug yog qhov tseem ceeb rau cov cuab yeej ua tau zoo thiab kav ntev. Cov chaw ua haujlwm sib txawv tso qhov kev xav tau sib txawv ntawm cov khoom xws li cov saw hlau, cov menyuam yaus, idlers, thiab sprockets.

Rocky Terrain:

Xaiv cov khoom hnyav hnyav thiab cov hlua khi hlua khi nrog kev hnav tsis kam. Forged sprockets thiab induction-hardened ntu muab kev cuam tshuam zoo dua.

Muddy lossis ntub dej:

Siv tus kheej tu cov khau taug qab thiab taug qab cov kev sib txuas nrog cov grousers dav. Ob chav flanged rollers pab tiv thaiv derailment hauv av tsis ruaj khov.

Mining lossis High-Abrasion Zones:

Xaiv rau cov idlers muaj zog, siab hardness bushings, thiab thicker khiav txuas. Chromium-molybdenum alloy steel Cheebtsam ua tau zoo nyob rau hauv abrasive hnav.

Huab cua txias:

Xaiv cov khoom uas muaj qhov kub thiab txias tiv taus cov ntsaws ruaj ruaj thiab roj. Tsis txhob nkim cov ntaub ntawv uas yuav tawg nyob rau hauv sub-zero tej yam kev mob.

Xuab zeb los yog suab puam:

Siv kaw hom rollers los tiv thaiv cov xuab zeb nkag. Txo kev sib txhuam los ntawm kev kho saum npoo thiab lubrication kom zoo.

Nco ntsoov ua raws li OEM cov lus qhia tshwj xeeb, thiab xav txog kev hloov kho tom qab muag raws li koj qhov chaw ua haujlwm. Cov khoom zoo txo qis qis thiab ua kom lub neej ua haujlwm siab tshaj plaws.

Vim li cas Heavy-Duty Sprockets thiab Rollers tseem ceeb heev rau Rocky Terrain?

Rocky struts nthuav tawm ib qho chaw xav tau tshaj plaws rau kev taug qab siv tshuab. Nthuav, pob zeb abrasive ua rau muaj kev cuam tshuam loj heev thiab kev sib txhuam, ua rau nrawm nrawm ntawm cov khoom hauv qab-tshwj xeeb tshaj yog sprockets thiab taug qab cov menyuam.

Heavy-duty sprockets, ua los ntawm high-strength alloy steel thiab induction-hardened rau HRC 50-58, yog tsim los tiv thaiv cracking, chipping, thiab deformation. Lawv cov hniav sib sib zog nqus tau muab kev koom tes zoo dua nrog kev sib tw bushings, txo qis qis thiab txhim kho torque hloov mus rau hauv cov khoom hnyav.

Taug qab rollersnyob rau hauv pob zeb struts yuav tsum tiv taus pounding thiab sab loading.Ob chav flanged, forged rollersnrog cov plhaub tuab thiab cov khoom siv cua sov yog qhov tseem ceeb rau kev ruaj ntseg, taug qab kev taw qhia, thiab kev pab lub neej ntev.

Yog tsis muaj kev txhawb nqa sprockets thiab rollers, feem ntau tsis ua haujlwm tuaj yeem tshwm sim - ua rau muaj kev poob qis, kev saib xyuas, thiab txawm tias muaj kev nyab xeeb. Heavy-duty Cheebtsam ua kom muaj kev ua tau zoo, tshwj xeeb tshaj yog nyob rau hauv mining, quarrying, thiab mountainous operations.

Broken SPROCKET

TRACK ROLELR

Post lub sij hawm: Aug-04-2025